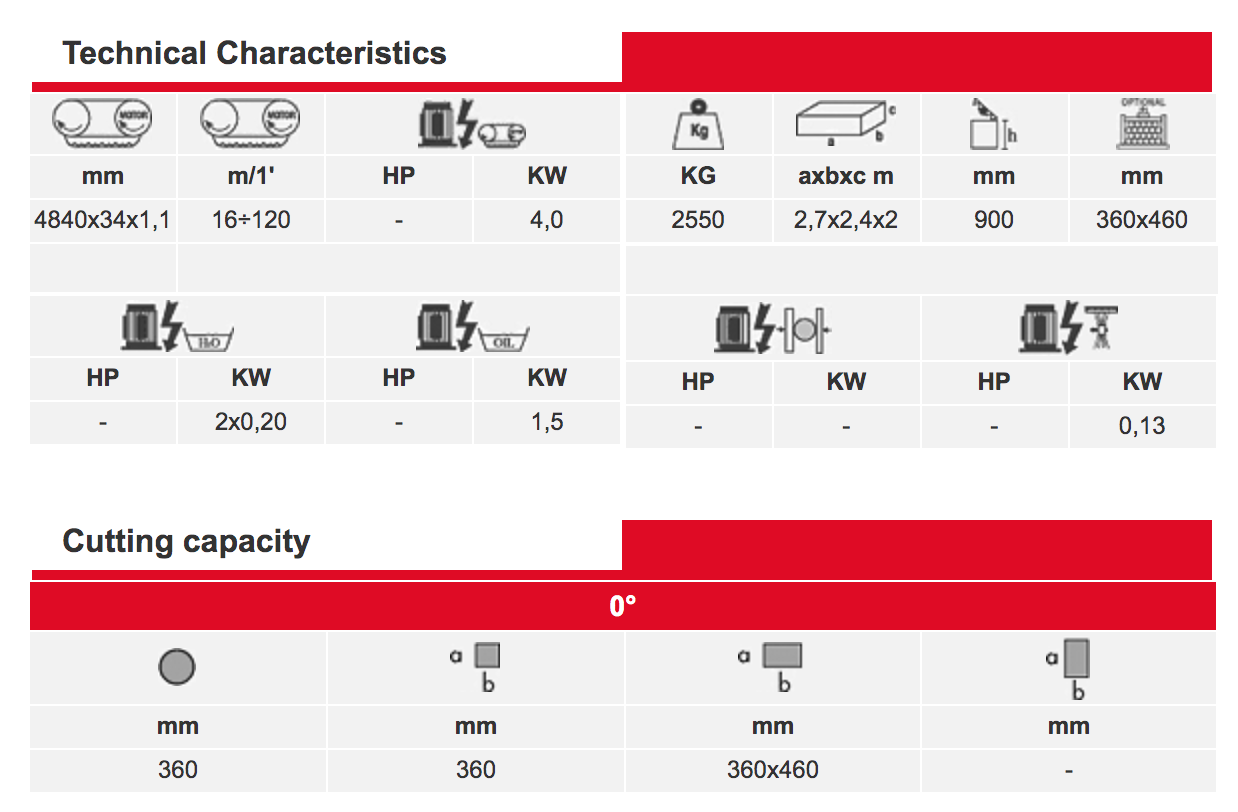

AUTOMATIC DOUBLE COLUMN BAND SAW MACHINE FOR CUTTING AT 0° WITH DIMENSIONS UP TO 360x460 mm. SHORTEST LENGTH OF RESIDUAL PIECE = 75 mm.

The machine is completely guarded, with an easy access for blade changing and ordinary maintenance. Possibility to load the material directly on the carriage by bridge crane. Standard screw chips conveyor, which can be assembled either on the right or on the left side of the machine. 600mm-stroke-feeding carriage with supporting structure, controlled by recirculating screw and encoder. Standard hydraulic blade tensioning by manual selector. Shortest length of residual piece 75 mm. Carriage vice and cutting vice equipped with full-stroke cylinders. LED working area lighting. Wide 130 l tank for cutting liquid with double water pump and 6 refrigerating utilities. Descent on double column with hydraulic cylinder and linear guides with recirculating-ball slides. Automatic positioning movable blade-guide arm. Carriage vice with moving back fixed jaw, to allow the processing of crooked bars. Lubricated and motorized blade-cleaning brush. Mechanical device for material presence detection on the feeding carriage. Blade speed control sensor. 10” touch screen control panel, software equipped with an innovative user interface and security PLC. The vertical vices optional does not affect the cutting capacity. Carriage moving back at the end of the cut to avoid any damage to the blade. Minimum cut length 5mm.