Colchester Storm VL-1000 with Integrated Meltio 3D Printing

Hybrid CNC Machining Center with Additive Manufacturing for Advanced Metal Processing

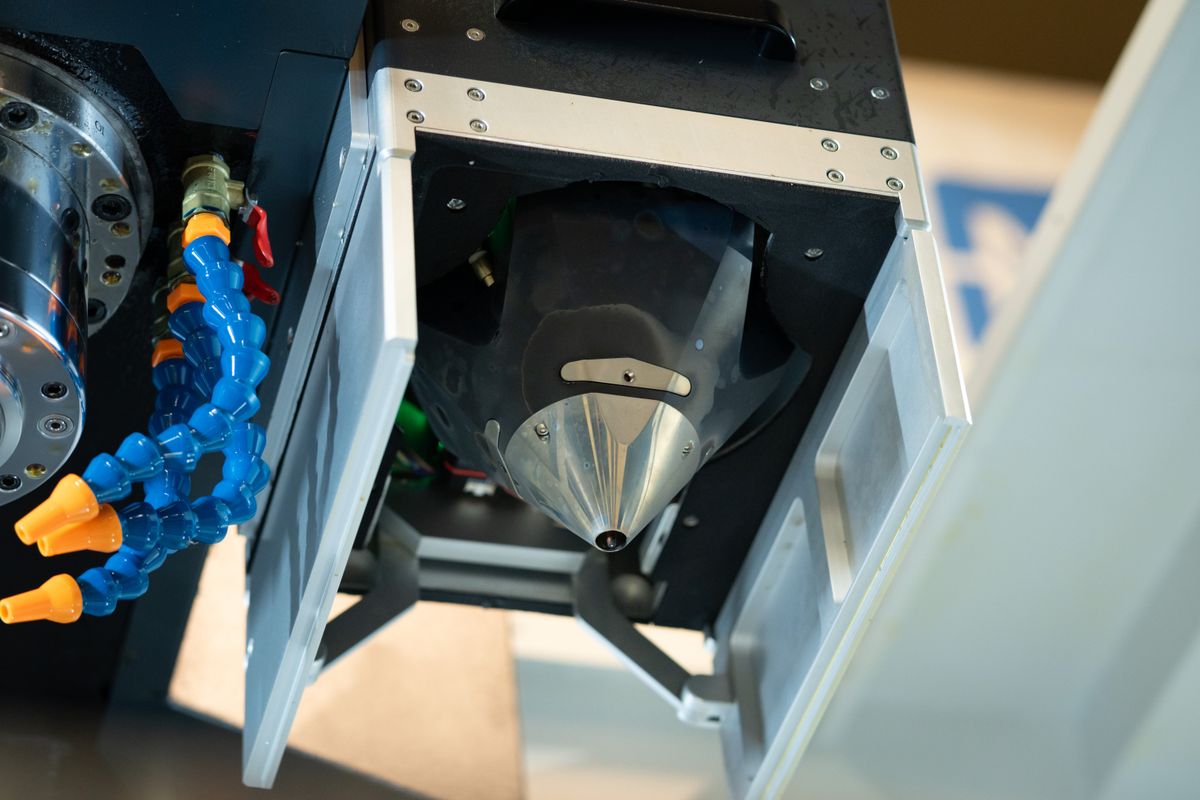

The Storm VL-1000 is a powerful vertical machining center from Colchester, now available with an integrated Meltio Engine for hybrid manufacturing. This combination enables both traditional CNC machining and advanced metal 3D printing in a single machine.

By integrating the Meltio Engine into the Storm VL-1000, you gain a flexible solution for producing complex components, repairing worn-out parts, and modifying existing workpieces. The system supports both Meltio IR and Meltio Blue laser heads, offering material versatility for a wide range of applications.

Key Specifications – Storm VL-1000:

- Travel (X, Y, Z): 1020 x 510 x 560 mm

- Spindle Speed: 10,000 RPM, BT40 taper

- Table Size: 1200 x 500 mm, max load 800 kg

- Rapid Traverse (X, Y, Z): 36 m/min

- Tool Magazine: 24-position twin-arm type

- Machine Weight: 5190 kg

Meltio Engine – Integrated Metal 3D Printing:

- Laser-based Directed Energy Deposition (DED) technology

- Material compatibility: Stainless steel, tool steel, titanium, Inconel, copper, aluminum, and more

- Ability to combine multiple materials in a single part

- High material efficiency – minimal waste

- Available with IR or Blue laser head for customized applications

Benefits of Hybrid Manufacturing:

✅ Machine and print in a single operation – save time and reduce post-processing

✅ Flexible material choices – use standard metal wire for cost-effective production

✅ Repair and modify components – extend the lifespan of critical parts

✅ Combine subtractive and additive manufacturing for unique design possibilities

This solution is ideal for workshops, industrial manufacturers, and R&D environments looking to merge machining and metal printing into one powerful system.

Roller Type Linear Guide Ways

The Linear Motion Guideways feature low friction and free from stick-and-slip problems. Such the characteristics are especially suitable for high speed 3D cutting and finishing. The quality of workpiece surface is increased and the need for manual polishing of workpiece surfaces is reduced.

Machine Specification

Control Fanuc Oi-MF with Manual Guide i

Siemens 828D with ShopMill

Travels

X, Y, Z (mm) 1020 x 510 x 560

Spindle nose to Table (mm) 150-710

Table

Working Area (mm) 1200 x 500

Max Load (kg) 800

T-Slots (No. x Width x Pitch) 5 x 18 x 100

Spindle

Spindle Taper BT40

Speed (rpm) 10,000 Belt Drive with Oil Cooler

Spindle Motor (Kw) Fanuc (7.5/11Kw)

Siemens (9Kw)

Feed Rates

Rapid Traverse X, Y, Z (m/min) 36

Max Cutting Feedrate (m/min) 10

Tool magazine

ATC 24 Station Twin Arm

Type BT40

Max Tool Diameter (mm) 80

Max Tool Weight (kg) 7

Max Tool Length (mm) 300

Dimensions

Net Weight (Kg) 5190

Power Requirement (Kva) 15

Floor Space (L x W x H) 2980 x 2955 x 3045mm

Standard Accessories

Screw Type Chip Auger and Cart

Spindle Air Blast

Coolant and Air Gun

Heat Exchanger

Spindle Oil Cooler

Portable MPG

LED Light

Coolant System

Cycle Indicator Light

Levelling Pads

CE

4th Axis Preparation

Colchester

Why Colchester Machine Tool Solutions?

- An installed base of over 100,000 Colchester and Harrison lathes worldwide

- All products from Colchester, Harrison, Pratt Burnerd, Clausing and Gamet are designed and manufactured to exceed the highest international quality and safety standards

- Stock machines and workholding available quickly

- Experienced, factory trained engineers and support staff offering speedy response to your needs

- Backed up by over £4 million of genuine manufactured spare parts

- The number one choice for industry and education globally