QC11K NC Hydraulic Guillotine Shearing Machine

- Three-point support rolling guide (Lower eccentric shaft, front support shaft, upper eccentric shaft)

- Do linear vertical motion

- Hydraulic oil cylinder do linear vertical motion

- 100% hydraulic pressure acting on cutting edge

- Adjustable cutting angle, different cutting angles are applied for cutting plates with different thicknesses

- Suitable for cutting thicker plate with better cutting quality

NC guillotine shearing machine provides high strength, productivity, sensitivity, and safety while lowering your production cost and improving your bottom line. This hydraulic shearing machine is the second generation hydraulic guillotine plate shears. Use advanced hydraulic integrated valve block. The structure is compact, the pipe connection is reduced, and the reliability and maintainability of the system are improved.

Main Feature

● Fully steel welded structure, with excellent rigidity and stability;

● Assisting blade pedestal on worktable is convenient for micro adjustment;

● Support ball is provided on worktable convenient operating for rolling plate;

● Provided with counting function for shearing to decrease the numerous artifical counting;

● NC Hydraulic Guillotine Shearing Machine advanced hydraulic integrated system is employed and the pipeline connection is minimized to ensure the system reliability and safety;

● International standard electrics and switchs;

● Front arms with ruler fixed on worktable;

● Blades gap adjustment by hand wheel;

● Motorised back gauge, reduce speed through gear;

● Can euip kinds of NC controllers: Estun E21S / E200S, Delem DAC310, DAC360, Maper HT071, Elgo P40 ect.

Standard Components

● Estun E21S NC controller

● Germany BOSCH-REXROTH hydraulic system

● Germany SIEMENS motor

● Sunny oil pump

● Taiwan HIWIN ball screw

● France Schneider eletrics

● Light alignment device

● Manual blade gap adjustment

● Motorized cutting angle adjustment

● Blade material 6CrW2Si

● Light curtain

Optional

● E200PS, DAC360, P40

● Rear pneumatic support

● Front feeding table

Controller Function

E21s

160x160 LCD display

Backgauge control

Control for general AC motors, frequency inverter

Intelligent positioning

Stock counter

Program memory of up to 40 programs, up to 25steps per program

One side positioning

Retract function

One key backup / restore of parametersmm / inch

Chinese / English

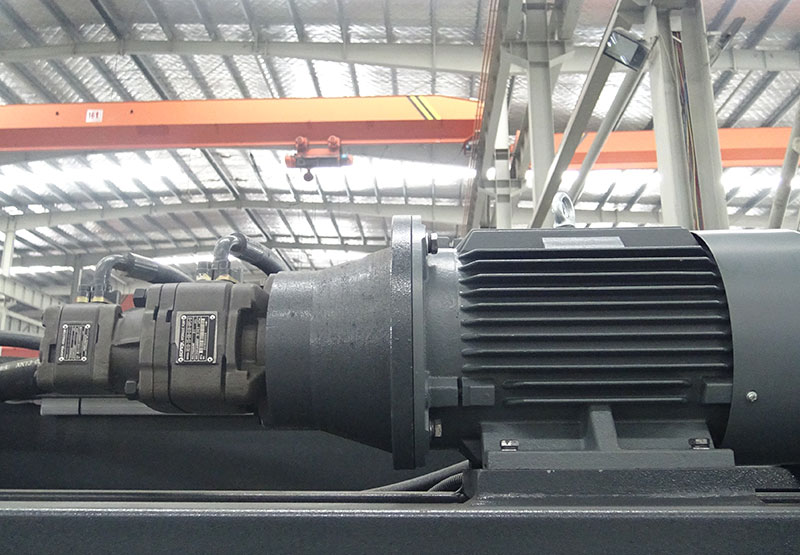

Main Motor

German famous brand Siemens motor improves the life span of the hydraulic shearing machine and keeps the machine working in low noise environment.

Hydraulic System

Using USA first valve make it more reliable and easy for maintenance.

Low sensitivity to oil pollution and assure of long service life

Electrical System

Schneider electrical components make the machine performing well even the electricity is not stable and customers can easily get the replacement anywhere in the world.

Front Table

Transfer balls on table can reduce surface scratches on the sheet and front support arms with ruler for easy feeding.

Ball Clearance Adjustment

Adjust the cutting blades gap by motor according the cutting thickness of the metal sheet can get better cutting permance

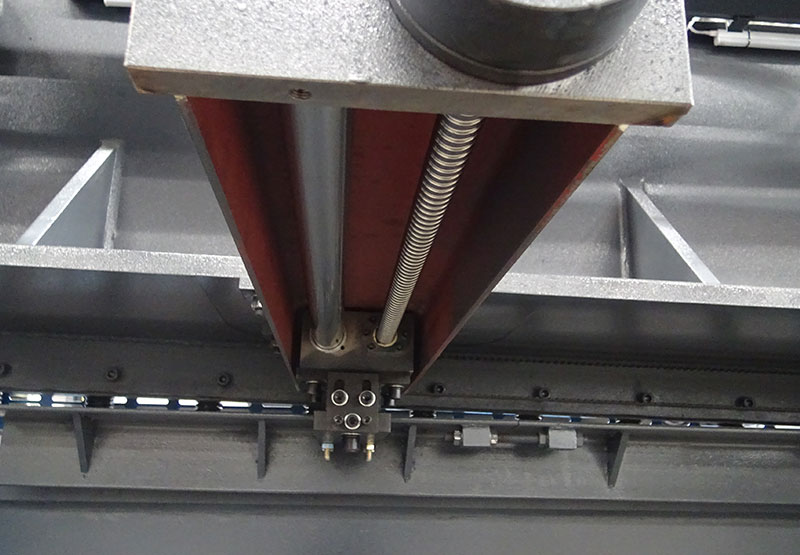

Ball Screw

ZYMT Backgauge system with Hiwin ball screw and slick rod for high precision.

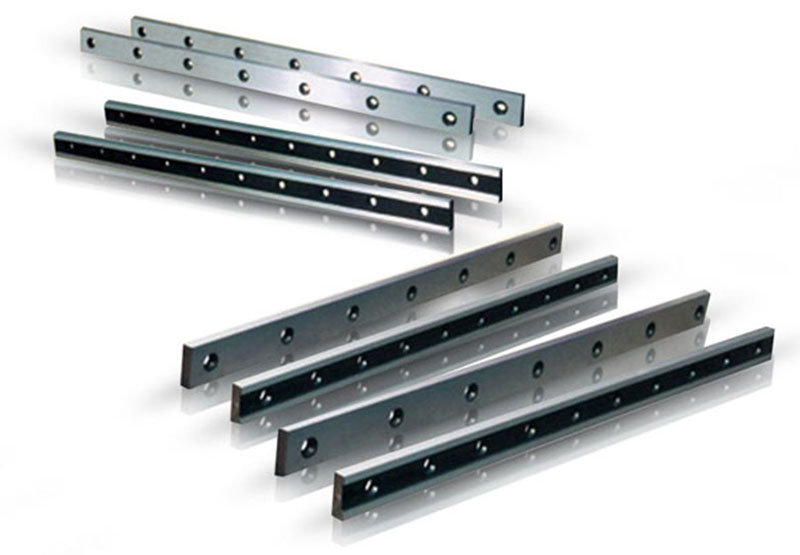

Blade

Blade with 4 cutting edges to provide a longer life span and reducing down time.

6CrW2Si Blades wit high tensile strength for cutting carbon steel and stainless steel.

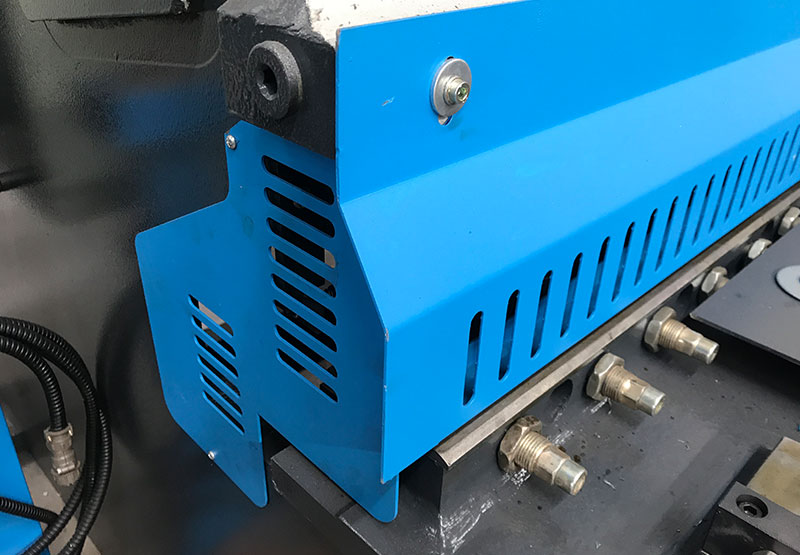

Safety fence

Protective guards on each side can protect the user during operation

Hydraulic Hold-down Pads

The lower end of the press cylinder is made of non-metal material, which has certain elasticity and large friction coefficient. When cutting the sheet, the press pad can be in close contact with the material plate to provide sufficient friction to effectively prevent the plate from being shaken during the shearing process.

Technical Parameters

| Model | Cutting thickness (mm) | Cutting length (mm) | Angle range (mm) | Backgauge stroke (mm) | Approx. weight (Ton) | Overall length (mm) | Overall width (mm) | Overall height (mm) | Main power (KW) |

| 6x2500 | 6 | 2500 | 1-3 | 20-750 | 4.2 | 3040 | 1740 | 2040 | 7.5 |

| 6x3200 | 6 | 3200 | 1-3 | 20-750 | 5.7 | 3750 | 1770 | 2150 | 7.5 |

| 6x4000 | 6 | 4000 | 1-3 | 20-750 | 8.5 | 4650 | 1840 | 2150 | 11 |

| 6x5000 | 6 | 5000 | 1-3 | 20-750 | 11 | 5750 | 1840 | 2150 | 11 |

| 6x6000 | 6 | 6000 | 1-3 | 20-750 | 14 | 6480 | 2100 | 2300 | 11 |

| 8x2500 | 8 | 2500 | 1-3 | 20-750 | 4.4 | 3140 | 1700 | 1700 | 11 |

| 8x3200 | 8 | 3200 | 1-3 | 20-750 | 6 | 3860 | 1700 | 1700 | 11 |

| 8x4000 | 8 | 4000 | 1-3 | 20-750 | 8.9 | 4750 | 1700 | 1700 | 11 |

| 8x5000 | 8 | 5000 | 1-3 | 20-750 | 11.5 | 5830 | 2400 | 2000 | 11 |

| 8x6000 | 8 | 6000 | 1-3 | 20-750 | 16 | 6480 | 2100 | 2350 | 11 |

| 8x8000 | 8 | 8000 | 1-3 | 20-750 | 29.5 | 8580 | 2130 | 2350 | 11 |

| 10x2500 | 10 | 2500 | 1-3 | 20-750 | 6.5 | 3240 | 1800 | 1700 | 11 |

| 10x3200 | 10 | 3200 | 1-3 | 20-750 | 8 | 3850 | 1830 | 1900 | 15 |

| 10x4000 | 10 | 4000 | 1-3 | 20-750 | 12 | 4750 | 2100 | 2000 | 15 |

| 10x5000 | 10 | 5000 | 1-3 | 20-750 | 16 | 5830 | 2100 | 2000 | 15 |

| 10x6000 | 10 | 6000 | 1-3 | 20-750 | 24 | 6500 | 2100 | 2300 | 15 |

| 10x8000 | 10 | 8000 | 1-3 | 20-750 | 32 | 6800 | 2100 | 2300 | 15 |

| 13x2500 | 12 | 2500 | 1-3 | 20-750 | 8.5 | 3285 | 1830 | 2390 | 15 |

| 13x3200 | 12 | 3200 | 1-3 | 20-750 | 10 | 3855 | 1830 | 2390 | 18.5 |

| 13x4000 | 12 | 4000 | 1-3 | 20-1000 | 13.5 | 4850 | 1830 | 2390 | 18.5 |

| 13x6000 | 12 | 6000 | 1-3 | 20-1000 | 26 | 6850 | 1930 | 2650 | 18.5 |

| 13x8000 | 12 | 8000 | 1-3 | 20-1000 | 46 | 8950 | 2130 | 2850 | 18.5 |

| 13x9000 | 12 | 9000 | 1-3 | 20-1000 | 65 | 9980 | 2300 | 2950 | 18.5 |

| 13x10000 | 12 | 10000 | 1-3 | 20-1000 | 85 | 11050 | 2500 | 3100 | 18.5 |

| 16x2500 | 16 | 2500 | 1-3 | 20-1000 | 13 | 3440 | 1940 | 2830 | 22 |

| 16x3200 | 16 | 3200 | 1-3 | 20-1000 | 15 | 4010 | 1940 | 2830 | 22 |

| 16x4000 | 16 | 4000 | 1-3 | 20-1000 | 16.5 | 5010 | 1980 | 2830 | 22 |

| 16x5000 | 16 | 5000 | 1-3.5 | 20-1000 | 25 | 5900 | 2600 | 2830 | 22 |

| 16x6000 | 16 | 6000 | 1-3.5 | 20-1000 | 31 | 6900 | 2700 | 2830 | 22 |

| 16x8000 | 16 | 8000 | 1-3.5 | 20-1000 | 75 | 8900 | 2900 | 3430 | 22 |

| 20x2500 | 20 | 2500 | 1-3.5 | 20-1000 | 17 | 3440 | 1980 | 2830 | 37 |

| 20x3200 | 20 | 3200 | 1-3.5 | 20-1000 | 20 | 4010 | 1900 | 2830 | 37 |

| 20x4000 | 20 | 4000 | 1-3.5 | 20-1000 | 22 | 4850 | 2600 | 2900 | 37 |

| 20x6000 | 20 | 6000 | 1-3.5 | 20-1000 | 50 | 6700 | 3000 | 3000 | 37 |

| 30x2500 | 30 | 2500 | 1-3.5 | 20-1000 | 29 | 3440 | 1900 | 2830 | 37 |

| 30x3200 | 30 | 3200 | 1-3.5 | 20-1000 | 38 | 4200 | 1900 | 3000 | 37 |

| 40x2500 | 40 | 2500 | 1-3.5 | 20-1000 | 38 | 3440 | 2000 | 3000 | 37 |

Competitive Advantage

● Competitive Pricing

Scientific cost control-higher production and lower price

● Technical Support

Professional and timely technical support--engineers from abroad

● Design Service

Our team has experience in all fields relating to product design and development. If you have any needs for your new product, we are here to offer our support.

● Delivery

The effective purchasing and fast production departments enable us to delivery the machines in time

ZYMT - Platemaskiner

ZYMT er en av Kina sine fremste produsenter av kantpresser og platesakser. De bruker europeiske komponenter og holder bra kvalitet ift. lav pris.